FAQ

¶ HOW ...?

¶ … to save column layout in StockM window?

If you want to save the layout of the columns, click “Three dots”

Then → Save current table setup → enter a name for the column settings.

If after re-entering StockM you see that the layout of the columns has not been saved - press "three dots" and select your saved setting.

¶ … to change the buffer for a certain day by the coefficient?

If you want to change buffers for a certain day by a coefficient:

1. Use seasons if you take the buffer from the previous period and it has already changed. MODULES -> SEASONS -> New:

1) specify "Name", "Begin of season";

2) select the start action: "Buffer change on begin date";

3) select "Calculate by buffer". The formula =Buf * 1 + 1 will open, where:

• Coefficient (first unit in the formula). For example To add 30% to the existing buffer value, enter 1.3

• Constant (the second unit in the formula) - the number you enter will be added, e.g. =Buf * 1 + 1 =3 * 1 + 1 = 4. You can specify 0 for the constant.

• Put the check mark if you want MOQ to be evaluated when calculating the new Buffer. Then it will calculate:

New BUF = (buffer - MOQ) * coef + MOQ.

• Do not put a checkmark if you want the MOQ not to be evaluated when calculating the new Buffer. Then it will calculate:

New BUF = buffer * coef.

• Specify which date (day) buffer you will change based on the coefficient.

4) in the "List of SKU" window, select the SKUs for which you want to change buffers;

5) select "None" for the end of season.

Note: If you add the same SKU to multiple seasons in the same storage location, the start of a later season will terminate the current season.

2. If you change the buffer of the current day, you do not need to enter the season. You can change the buffer by a coefficient in the ASSORTMENT window in the "New buffer" column:

1) stand on the required SKU line in this column;

2) press the buffer calculation icon ;

3) in the window that opens, check "Calculate by coefficient" - > indicate the size of the coefficient;

4) specify whether to evaluate MOQ or not.

• Put the checkmark if you want MOQ to be evaluated when calculating the new Buffer. Then it will calculate:

New BUF = (buffer - MOQ) * coef + MOQ.

• Do not put a checkmark if you want the MOQ not to be evaluated when calculating the new Buffer. Then it will calculate:

New BUF = buffer * coef.

5) Click "Calculate".

p.s. if you want to recalculate buffers for several SKUs at the same time, after marking the SKU lines, click "Edit selected" -> in the opened window next to "New buffer" check "Calculate buffer" -> click the buffer calculation icon and follow the steps described above.

¶ … to change the buffer when changing frequency of the orders?

In case of the significant change of the supply cycle it is necessary to recalculate buffer in order not to run out of SKUs.

Formula for calculating the new buffer:

(Old buffer - MOQ) * coefficient + MOQ = new buffer

We calculate the coefficient by the formula:

New supply cycle / old supply cycle = coefficient

For example:

1. Order frequency 2 times per month (14 days)

Supply time 14 days

Old supply cycle 28 days

2. Order Frequency 1 time per month (30 days)

Supply time 40 days

New supply cycle 70 days

Coefficient: 70/28 = 2, 5

NOTE

-when the supply cycle is increased, the buffer must always be changed to ensure that the SKUs do not run out.

-when the supply cycle becomes shorter it is necessary to analyze each case separately, as the decision to recalculate the buffer depends on how much the cycle is shortened;

- you do not need to recalculate the buffer when you reduce the order frequency due to unformed orders, it will be managed by the system.

¶ … to make settings in StockM when several managers work with the SKU of the same supplier?

1. Assign the respective manager to the SKU: ASSORTMENT → Manager

If manager information is updated through data exchange from accounting, assign the correct managers in accounting.

Check if the cards of these managers have been created in SM Admin → Settings → Users (users) cards and if the manager codes that we will receive during the data exchange are assigned to them (you should check if the managers are new. This can be done by a user with StockM Admin rights). If the managers' codes (Reference code) are not entered, assign them.

2. If you want the orders to be formed separately by manager, then: LISTS → SUPPLIERS → open the Supplier card with a pencil → Order data → put a check mark on "To split the order by responsible manager" → click "Save".

3. If you want the orders to be split based on the split mark as well, put a check mark next to "To split the order by split mark". The system will first create orders based on the managers responsible for the SKU and further split them according to the split mark assigned to the SKU.

.jpg)

¶ … to act when SKUs are removed from assortment or refused by the supplier?

1. If SKUs are removed from the assortment and will not be ordered from other suppliers with those codes, in such case:

1) make the supplier inactive if no SKUs will be supplied from the supplier: LISTS → SUPPLIERS → Find the required supplier → Open the supplier card via "pencil" → Uncheck "Active" → Click "Save".

2) make the order formation schedule inactive if no SKUs will be supplied from the supplier: PARAMETERS → SUPPLIERS SCHEDULE → Filterout supplier supply schedules → Uncheck "Active" → Save by pressing Enter.

OR

remove the supplier's order formation schedule if no SKUs will be supplied from the supplier: SETTINGS → SUPPLIERS SCHEDULE → Filter out supplier supply schedules → Mark the schedule → Click "Delete Selected".

3) change the statuses of the SKU:

• if there is no SKU balance, specify status NA: ASSORTMENT → Filter out supplier SKU → Mark all lines → Click "Edit selected" → Specify status NA → Save.

• if there is a balance, mark OUT for such SKUs: LISTS → SKU → Open SKU card via "pencil" → assign OUT type = OUT.

2. If there will be no work with the supplier, but SKUs with the same codes will be purchased from other suppliers, then:

1) make the old supplier inactive if no SKUs will be supplied from the supplier: LISTS → SUPPLIERS → Find the required supplier → Open the supplier card via "pencil" → Uncheck "Active" → Click "Save".

2) make the order generation schedule of the old supplier inactive if no SKUs will be supplied from the supplier: PARAMETERS → SUPPLIERS SCHEDULE → Filter out supplier supply schedules → Uncheck "Active" → Save by pressing Enter.

OR

remove the supplier's order generation schedule if no SKUs will be supplied from the supplier: SETTINGS → SUPPLIERS SCHEDULE → Filter out supplier supply schedules → Mark the schedule → Click "Delete Selected".

3) activate the new supplier's card, if the supplier is new and no other SKUs have been shipped from it: LISTS → SUPPLIERS → Find the required supplier → Open the supplier's card via "pencil" → Check "Active" → Click "Save" .

4) create an order supply schedule for a new supplier, if the supplier is new and no other SKUs have been shipped from it: PARAMETERS → SUPPLIERS SCHEDULE → New → Fill in the required fields → Click "Create".

5) change supplier to SKU:

• if the supplier is updated from accounting, change the supplier in the accounting program and after the data exchange, the information will be updated in StockM'e;

• if you change the supplier in StockM, you can do it in the "ASSORTMENT" window: Filter the SKUs for which you need to change the supplier → Mark the rows → Click "Edit selected" → Choose the name of the new supplier → Save.

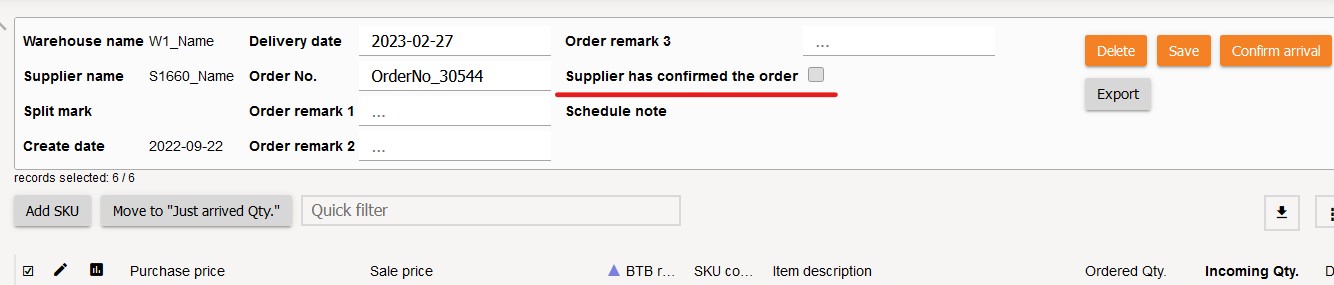

¶ … to mark that the supplier has confirmed the order?

If after sending the order to the supplier, it is necessary to receive his confirmation about the order, the following confirmation can be marked in StockM:

• LISTS → SUPPLIERS → filter the required supplier → open his card via "pencil" → Order data → specify the number of days within which the supplier must confirm the received order under the setting "Supplier has to confirm the order in xxx days".

• When the supplier confirms the order, in the list of incoming orders: ORDERS → PLACED → in the line of the required order, put a check mark in the column "Supplier has confirmed the order" -> Save

OR

Inside the placed order: ORDERS → PLACED → filter the required order → Open the order inside via "pencil" → Put a check mark in the "Supplier has confirmed the order" → Save.

- If the user does not put checkmark within the specified number of days, the "Unconfirmed Orders" task/signal appears in the task bar. Find out why the supplier does not confirm the order, and if the confirmation has already been received, note it in StockM

¶ … to set up warehouse information on the order form?

When you want to see the information of the storage location from which the order is sent in the order form, you must enter it in the SM Admin module (only a user with Admin rights can connect to the SM Admin module):

• Log in to SM Admin;

• Menu: SETTINGS → WAREHOUSES → Filter the required storage location → Open the warehouse card via "pencil" → Enter the information you want to see in the order at the storage location in the "Warehouse order credentials (in order form)" field → Save .

¶ … delete/remove split mark for SKU?

When you want to remove a split mark assigned to an SKU:

• Filter out SKUs in the assortment window;

• In the "Split mark" column, select "Empty split mark". If you don't see the column, expand it through three dots → Select the visibility of columns → In the list of columns that are not displayed, check "Split mark", it will jump to the list of displayed columns → click "Confirm the setup";

• Save - press the Enter key.

To remove the split mark for SKU list:

• Filter the necessary SKUs in the assortment window;

• Mark the rows for which SKU you want to remove the split mark;

• Click "Edit selected";

• In the marked lines editing form, select "Empty split mark" next to the "Split mark" field;

• Click "Save".

¶ … remove the SKU from the ALT group?

You can separate/remove a SKU from an alternative (ALT) group:

• LISTS → SKU → select the SKU row → click "Edit ALT group" → select the SKU row you want to remove from the group → click "Remove SKU" → Save.

OR

• Open the SKU card → click "Edit ALT group" → mark the SKU line you want to remove from the group → click "Remove SKU" → Save.

Disconnecting the ALT status SKU from the group will change the status to ND and you will see the SKU among the new incompleted SKU data.

p.s. The ALT group is automatically dismantled when the status of the main SKU is changed to NA in all storage locations. SKUs in ALT status are then disconnected from the main SKU and automatically changed to NA.

¶ … is the reliability of the supplier calculated in StockM?

In order to assess the supplier's reliability, you need to know how accurately and on time the supplier delivers orders.

• Any deviation (too small or too large quantity delivered) from the sent order reduces the supplier's reliability. For example, if you ordered 100 lines and the supplier delivered 120 lines – supplier's reliability is 100/120 i.e. 83%

• Delivery of the order not on time (delayed) also reduces reliability.

¶ … is calculated the lost sales?

Lost sales are only calculated for *TA SKUs with a balance ≤ 3% buffer. It checks how many days per week the SKU met this condition and the resulting number of days is multiplied by the average daily sales.

• average sales are calculated at purchase prices.

• if the SKU is set OUT type, lost sales are not calculated, regardless of status.

¶ … are calculated ROI and turnover in StockM?

ROI is the ratio of margin and average inventory at purchase prices (that is visible/transmitted to StockM) or annualized return on inventory investment ie. how much you earned from the stock The numbers are more indicative intended for monitor trends.

Turnover is the ratio of sales and inventory at purchase prices.

¶ … how do PTO priorities working?

PTO priorities works depending on the supply chain and are valid for the storage location where the PTO reservation is made, the priority works through one supply chain:

• When the PTO is located in a regional storage location and is supplied to it from the Central warehouse: the amount of PTO is reserved in the Central warehouse and is not distributed to other storage locations according to regular orders. With the nearest supply, the SKU will be delivered to the warehouse location with PTO. If the PTO is from more than one storage location, priority is determined based on the supply schedule.

• When the PTO is located in a storage location where the SKU is supplied by an external supplier, the priority is not determined, all PTO SKUs are prioritized and added to the regular order generated for the supplier according to the schedule.

¶ WHY ...?

¶ … storage location data is incompletely updated?

Storage location data may not be updated if during the data exchange, no information was transferred from accounting or less information was transferred than expected by StockM.

You can see the status of the system data exchange: in the taskbar -> Data import.

• SKUs that have not been updated for more than 7 days can be seen in system warnings. SKUs that don't update distort the reports. Autocorrect will turn off (set status to NA) and annul the balance for SKUs that have not updated in more than 30 days.

• View the list of SKUs. If you do not manage SKUs in StockM, i.e. you will not transfer data about them through the exchange, assign the status NA. In this case, the system will not wait for data (only waits for active SKUs). Refresh percentage (Updated) will increase - will not throw an error if it reaches the specified threshold percentage.

¶ … no order created?

If you see no orders created, check:

• whether the data exchange was successful: taskbar → Data import;

• whether there is an order supply schedule created for the supplier: PARAMETERS → SUPPLIERS SCHEDULE → the supply schedule for the storage location must be entered and active;

• are there any SKUs that need to be ordered: ASSORTMENT → specify the supplier, warehouse, value "Amount to order" > 0 in the filter;

If the data exchange was successful, the order should have been formed according to the supply schedule and you can see in the assortment window that there are SKUs that need to be ordered, form a new order manually: ORDERS -> CREATE A NEW ONE -> specify the necessary information and click "Create orders".

¶ … SKU don't fell it to regular order today?

If the SKU do not fell to your regular order, please check:

• whether SKU status is *TA. You can check this in the ASSORTMENT window.

• whether the supplier is assigned/specified for SKU. You can check in the window ASSORTMENT → Supplier code or Supplier name.

• whether there is an order delivery schedule created for the supplier: PARAMETERS → SUPPLIERS SCHEDULE → an active delivery schedule for the storage location must be entered;

• whether "Next order date" is today: ASSORTMENT → Next order date;

• whether the buffer is indicated for the SKU;

• maybe there is a quantity on the way and the SKU is already on its way: ASSORTMENT → On the way Qty.;

• is there a demand to order a SKU: ASSORTMENT → specify the SKU, warehouse in the filter → you will see the demand in the "Amount to order" column;

• whether the SKU parameters are correct, or whether the MOQ and USQ values are correctly specified. MOQ must be a multiple of USQ.

• if the supplier is a central warehouse, check if there is enough stock. If the SKU orders had to be formed from several departments, maybe there was not enough balance in the center.

• security buffer1 may be specified in the central warehouse. If it exists, the system does not divide this quantity for warehouses

¶ … does the system offer to order exactly such quantity?

The following indicators shall be evaluated to calculate quantity to be ordered :

1. Status.

2. Buffer.

2. Balance.

3. Quantity on the way.

4. Reservation.

5. Security buffer.

6. Special order quantity.

7. MOQ/USQ

¶ … does not allow you to enter the ordered quantity with a comma?

If there is a need to enter the ordered quantity with a comma, check whether the dimension format is not specified as an integer: LISTS -> DIMENSION-> For the required dimension in the "Precision" column, specify how many decimal numbers you want to see after comma.

If you don't see the Precision column, open it through the column visibility options "Three dots".

¶ … compared to accounting, the wrong SKU balance is visible in StockM?

If you notice that the balance in StockM and Accounting is different, please check:

• whether the data for this SKU has been updated on the current day. You can see this in the SKU schedule. A black dot on the x-axis indicates that the data has not updated.

• maybe the SKU has alternative codes. If the SKU code is the main one, its balance includes the balance of the ALT SKU.

¶ the order sent automatically if the optimization conditions are not met?

If the supplier's card contains optimization conditions for auto order and you think that the order sent not according to them, first check whether the optimization conditions are specified for that storage location.

¶ StockM'e does not show quantity of SKU on the way?

If the order was sent and not yet arrived and you do not see the quantity on the way for the SKU, please check that the order was created with the quantity on the way. In the status column of the PLACED orders window, you can see what order has been created.

- if you see a picture of a truck in the order status column, it means that the order has been sent with quantity on the way (regular or special order with quantity on the way).

- If you see a picture of a person - it means that it is a special order (without quantity on the way).

¶ … SKU buffer changed?

The SKU buffer in StockM'e can be recalculated and changed:

• the system automatically, if in the supplier's card: LISTS → SUPPLIERS → opening the supplier's card with a pencil → General data → "Auto increase" and "Auto decrease" check marks are placed in the buffer management settings.

The system checks the buffers daily and if the relevant conditions are met, the buffers are recalculated and replaced.

• system automatically if SKU is specified/entered season. According to the conditions specified by the user during the season, the system can change the buffer at the beginning or at the end of the season.

• Manually by the user.

• When changing the order quantity in an didn't send (ORDERS → TO BE SENT) order. If the user changes the quantity in the order and the check mark "Replace buffer" is placed, then the buffer will be replaced by the difference in quantity (if there is at least a 10% difference).

¶ … after putting the SKU OUT type, it falls into the list of "Incompleted SKU data" the next day or later?

Such a situation occurs when the OUT procedure is automatically change SKU status to NA, but with data exchange we receive information from accounting about any "movement" of this SKU: balance, sale or transfer operation, write-off, etc.

With each data exchange, SKUs are checked and if a SKU with NA status receives e.g. a balance, the system automatically changes the status to ND and the SKU falls into the list of new incompleted SKU data. This is a signal to the user that the SKU is inactive, but movement has occurred. You need to decide what to do:

• if the SKU will be storage (must have) again at the storage location, give the status *TA and remove the OUT type;

• if the SKU will to be not storage at the storage location, change the status to *TO. The OUT procedure itself will transfer the state to NA when the balance is used up.

¶ WHEN...?

¶ … is SKU assigned NA status?

If the SKU is inactive, it will not be in the assortment, StockM'e data is not updated for it from accounting, assign status to NA for SKU.

When SKU data is not updated for more than 7 days it falls into a system wornings. After clicking the "Fix" button, the automatic correction will set the status to NA and reset the balance to zero for SKUs that have not updated in more than 30 days.

¶ … the mark NEW is assigned to the SKU?

The mark NEW is assigned to all newly occurred SKUs and is assigned for 3 months from the day the card or balance first appeared (was created) in StockM

¶ … the mark OUT is assigned to the SKU?

Mark "OUT" is assigned to the SKU taken out from the assortment. . This can be done by:

• LISTS → SKU → select the OUT in the "OUT Type" column

or

• In the SKU card → SKU in the company → select the OUT in the OUT type field.

The OUT procedure will automatically monitor the balance and change the status to NA when all the balance in the storage location is sold (p.s. the final OUT type status can be selected in SM Admin)

¶ … a mark A is assigned to the SKU?

This mark is assigned to a SKU of *TA status, if the SKU is falled in the list of SKUs that generate 80% of the turnover. The system makes recalculations every month, usually on the first day of the month.

¶ … a mark C is assigned to the SKU?

This mark is assigned to a SKU of *TA status, if the SKU is falled in the list of SKUs that generate 5% of the turnover. C mark can also be assigned to SKUs with OUT or NEW marks. The system makes recalculations every month, usually on the first day of the month.

¶ … to use PTO order?

A PTO order is used when there is no SKU balance at the warehouse where the order is placed. It can be entered in StockM or received from accounting in a pto.csv file.

¶ … and based on what data does the system suggest increasing and decreasing SKU buffers?

When recalculating the buffer, StockM checks whether the supply time has passed since the last buffer change. Then:

• Evaluates the size of MOQ;

• Checks in which zone the balance dominates;

• Is the SKU A, C mover, etc.;

• Checks if there was at least one replenishment since the last buffer change;

• Checks the balance of the central warehouse;

• Were there no refunds to the supplier, write-offs;

• evaluates sales over a certain period of time;

• Other conditions.

¶ OTHER QUESTIONS

¶ What is the difference between a regular order and a special order?

The system forms a regular order based on the demand calculated by StockM. The quantities that the system will add to the order can be seen in the ASSORTMENT window, in the column "Amount to order".

Regular orders can be of two types:

• a regular order is formed by the system according to the supply schedule;

• a regular order is created manually. Manual formation may be necessary if an order has not been created, although it should have been created, or it is necessary to send the order at a time other than that specified in the supply schedule.

After sending a regular order, the ordered quantities will be visible "on the way" ("On the way Qty." column in the ASSORTMENT window).

Special order is created only by hand. Such orders are used to order quantities not according to the system, for example: initial SKU distribution, one-time promotion coordinated with the supplier, etc.

A special order can also be of two types:

• special order with quantity on the way. Used when you want the ordered quantity to be visible and the system to estimate it when forming regular orders. Ordered quantities will appear as "On the way Qty.";

• special order without quantity on the way. Used when the order quantity should not affect regular orders. The ordered "On the way Qty." will not be visible.

¶ At what prices are sales calculated?

StockM sales are calculated at purchase prices.

¶ Uncheck the activity for a supplier we no longer work with?

If the SKU supplier is being changed, uncheck the activity for the previous SKU supplier: LISTS → SUPPLIERS.

If the activity is not removed, but a different supplier will be assigned to the SKU, left the previous supplier's activity will not be affect any processes. Orders will be created for the assigned supplier, just the old supplier will be visible in the windows of active suppliers and supply schedules.

¶ What can I do to prevent the buffer from getting too low?

If you want to stock a larger quantity of SKUs in the storage location than the system recommends, set a minimum buffer: ASSORTMENT -> enter the value in the column "Min buffer". It will prevent the system from reducing the buffer below the set limit.

Buffer value cannot be lower than MinBuf or MOQ. For example: tires can be sold one unit at a time, but usually the customer buys a complete set, i.e. four. In this case, if the minimum buffer is set to 4, the system will not lower the buffer below 4, regardless of sales.

¶ Do you need to change the buffer when a delivery time changes?

There are two options:

• When the delivery cycle is extended (rare shipments), because when forming orders in the previous delivery cycle, the minimum order amount is not formed each time (the system evaluates this), in this case, if the delivery time is extended up to 2 times, the buffer does not need to be recalculated.

• If there is a situation where the minimum order amount is generated every time with a shorter delivery time, then when the delivery time is extended, increase the buffer by the coefficient by which the delivery time increased.

¶ What settings should be set to evaluate the number after the decimal point when recalculating the buffer?

If the SKU is a variable quantity, the buffer and MOQ values can be a value with a number after the decimal point. In order for the buffer recalculation to take place by evaluating numbers after the decimal point, on the unit of measurement card: LISTS → DIMENSION → For the required dimension in the "Precision" column, specify how many decimal numbers you want to see after comma.

If you don't see the Precision column, open it through the column visibility options "Three dots".